Saving Time, Money & Maintenance

Regenerative braking systems offer significant advantages for fleets.

Anyone who has driven a hybrid or battery electric vehicle is familiar with regenerative braking. In essence, an electric motor or generator is used to “decelerate” the vehicle when the throttle is lifted. The aim is to use the kinetic energy that’s created to slow down the vehicle, and turn that energy into electricity that can charge the vehicle’s battery system and extend the electric range of that vehicle.

Many hybrids and EVs employ what’s called coast regeneration where the braking force is increased when the throttle is lifted, and the vehicle is essentially coasting.

Overlay regeneration

Then there’s overlay regeneration, which is added or “overlayed” onto conventional friction braking when the driver hits the brake pedal, as well as a more sophisticated blended regeneration. Here, the vehicle essentially “balances” friction and regenerative braking, depending on the availability of the latter and the driver’s input. The objective, is to maximize energy recovery, thereby improving vehicle efficiency and overall electric range.

These types of systems can take some getting used to. Drivers may feel that the vehicle is dragging the brakes whenever they lift their foot off the accelerator or depress the brake pedal. It may feel as though a calliper is sticking or the brakes are binding.

Clear gains

For fleets, where TCO and operational efficiency are key, vehicles equipped with regenerative braking systems have demonstrated to have several advantages.

At Geotab, Senior Manager Vik Sridhar notes that real world data has shown clear gains with fleets that are using vehicles equipped with regenerative braking systems.

Zeroing in on plug-in hybrid vehicles, data showed that among two groups of vehicles (one that was consistently plugging-in the vehicle and maximizing its electric range, versus using the internal combustion engine all the time), the former realized a 45% reduction in overall running costs and a 73% reduction in fuel consumption.

Additionally, Sridhar notes that Geotab’s own data points to significant maintenance and parts savings with regenerative versus conventional vehicle braking systems.

“Our studies have shown that [with regenerative systems] you’re extending your brake pad lifespan more than three times longer. In some cases, we’ve seen vehicles go 100,000 km (60,000 miles) before requiring brake pad replacement”.

Data like this illustrates that fleets are not only able to save on fuel consumption, but they can also save significantly on maintenance costs and downtime, bolstering TCO and overall operational efficiency. “Every time you have to bring a vehicle into a service centre for repairs, that’s taking time away from it being on the road,” says Sridhar. In other words, maintenance means reducing a vehicle’s ability earn its keep.

Maintenance considerations

Nevertheless, there are considerations, particularly when it comes to maintenance. At Holman, Holly Vollant, Manager, North American Remarketing explains that hybrids require careful attention when it comes to regular types of repairs and hybrid component-specific maintenance. Regenerative braking systems require regular inspections of the moving parts, including springs, shoes, callipers and rotors to prevent corrosion build up, particularly if the vehicles are operated in areas that are subject to snow and ice during winter, or to excessive moisture. Furthermore, regenerative braking impacts tire performance and wear, meaning tires should be inspected regularly, and fleets may have to budget for more frequent tire replacements when operating these types of vehicles.

While some components, such as brake pads, shoes and rotors will not need replacing as frequently, they still need to be inspected. Geotab’s Sridhar says he’s seen cases where certain fleets, such as those that operate delivery vehicles, have an annual brake inspection. This gives technicians the opportunity to examine and clean brake components, lubricate calliper pins and brake pad contact points to prevent rust from building up, which will ultimately cause parts to seize.

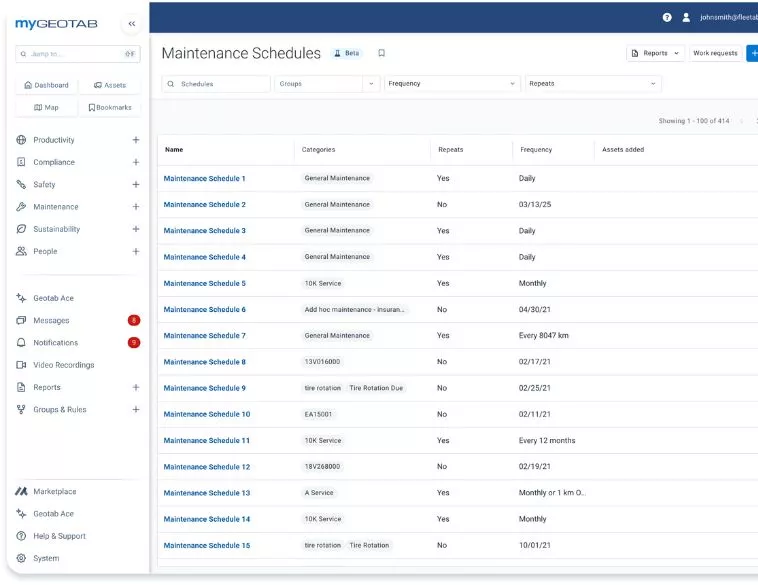

Sridhar stresses that when it comes to maintenance and service on hybrids equipped with regenerative braking systems, fleets should base maintenance schedules on actual wear and not a pre-set distance, as they could be simply wasting money and resources by doing so.

Driver Training

A big part in maximizing the effectiveness of regenerative braking boils down to driver training. Geotab’s Sridhar says that data clearly shows that the highest rates of energy capture are achieved when drivers slow the vehicle gradually, and well in advance of needing to come to a stop, as opposed to applying the brakes harshly at the last minute.

Another interesting observation is that by properly educating drivers, fleets can train them to have impactful results on maintenance. Sridhar says one example is training drivers to use the brakes on purpose at times.

“Performing a few firm stops from higher speeds each week can help keep the rotors and pads clean and functional,” he says, “thereby extending system and component life and reducing maintenance requirements.”

He notes that today, telematics data provides fleet managers with real insights into driver behaviour, which allows them to make more informed decisions related to driver training and education. “By feeding these data points into your coaching program,” he says, “fleets can optimize driver training and best practices behind the wheel, bolstering efficiency and overall profitability by properly leveraging both driving techniques and the advantages offered by regenerative braking systems.”