Holman Raises Eyebrows at Miami Event

This FMC is poised to tackle an unpredictable future.

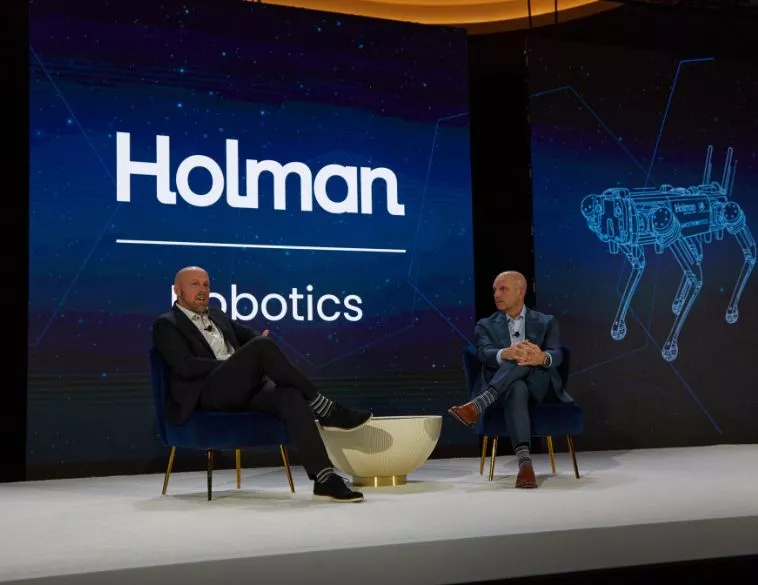

Holman CEO, Chris Conroy, kicked off the company’s annual fleet conference with a major announcement about the launch of the company’s newest business vertical: Holman Robotics.

“You many not think that robotics affects your business,” Conroy told the audience, “but it does.” He explained that automation and robotics are driving businesses today, due to both a lack of skilled labour, and the boost in efficiencies that are only possible with automation.

“We understand that our role is to help companies run their businesses better, and not just their fleets better,” he added, noting that Holman Robotics will benefit fleet customers, as well as other businesses.

Uncertain future

Holman’s annual fleet conference, Drive25, took place in Miami Beach, Florida from Nov. 4-6, with the biggest turnout of fleet professionals to date from all over North America.

Conroy said that Holman Robotics is the company’s eighth vertical, and admitted that no one is really sure how robots and automation will change the world, simply because things are changing so quickly.

He sees Holman’s role in this ever-changing world as a trusted advisor that can help fleet professionals navigate and manage all the possibilities. “We want to help you figure out what to use, how to set it up, how to manage the robots, as well as how to get the most out of the data that your robots will collect in order to find areas that need improvement,” Conroy explained.

Conroy was joined on stage by Joe Foster, VP of Holman Robotics, and by a surprise guest, Holman’s very own dog-like robot. Foster explained that the canine robot was currently equipped with a camera that would allow it to “see” and report back with information about a given area that it has been told to patrol. However, that same robot can be equipped with a variety of sensors that would allow it to detect radiation, chemicals and other substances.

Foster explained that instead of taking jobs away from humans, he believes that robots will take over assignments that humans either don’t want to do, or shouldn’t be asked to do, because they’re too dangerous. “We’re not trying to replace fleet drivers with robots,” he added. “Instead, we see robots doing the dull, dirty and dangerous jobs. That’s what they’re for.”

Economic outlook

Jeremy Robb, Senior Director of Economic and Industry Insights at Cox Automotive offered an overview of the U.S. economy, with a focus on how tariffs are changing the economic landscape.

He explained that although Americans are seeing lower interest rates, lower taxes and less regulation in the U.S., “real tariff costs are not yet baked into product decisions.”

Robb said that as far as the automotive industry is concerned, tariffs are lowering overall sales volumes. “Tariffs are real, and they’re not going away,” he added.

According to Robb, tariffs are adding USD $5,500 to the cost of a vehicle sold in the U.S., if it’s imported from abroad; USD $4,900, if it’s imported from Canada or Mexico; and USD $1,000 if it’s assembled in the U.S.A. This translates into an average of 4-8% increase in the price of a vehicle, whether it’s new or used.

Currently, U.S. dealers seem to be eating that cost, Robb explained, which has resulted in lower profits per vehicle for retailers. This means that tariffs are not hitting consumers as hard as they would have, had dealers passed the costs on to the end user. Even so, Robb explained that the new vehicle average transaction price rose above USD $50,000 for the first time ever in the U.S., which means that affordability is a major concern.

Tech insights

A panel discussion moderated by Peter Nogalo, Manager, Industry Relations at Holman tackled the challenging topic of artificial intelligence (AI). One of the panelists, Jarrod Phipps, Executive VP & CIO Holman said that AI will improve productivity and efficiency.

“Humans get tired, but AI doesn’t,” Phipps said. “That means it can analyze data and get answers much faster.” He compared AI to an exoskeleton, like an Ironman suit, that improves a human’s ability, but doesn’t replace them.

He admitted that AI comes with risks. “I’m less scared about the technology than the rapid pace of adoption,” Phipps added. “Mistakes are possible, and AI is prone to bias. To mitigate risk, we’re getting humans involved in the process. We’re not leaving all the decision-making to AI.”

Gregory Allen, VP of Information Management at Holman explained that it’s important to view data differently when using AI. For instance, we can no longer think of data as numbers on a spreadsheet that we feed into a computer, because in addition to analyzing that kind of hard data, AI can read our emails and access files on our computers. It then takes all that information into account when answering our questions.

Mike Stallone, VP of Software Engineering at Holman took the idea one step further. “AI can take all the knowledge of the Internet and apply it to the problem you’re trying to solve,” he explained.

Sebastian Ramirez, Director of Product Management-Mobility Payments at Wex noted that we can ask AI to analyze data and give us answers to complex questions. “If you want to know the total cost of ownership of a vehicle and when to remarket it, AI can answer those questions without you having to do the math yourself,” he said.

Peer panel

A panel discussion moderated by Kathryn Foster, Director of Strategic Services at Holman tackled a number of timely topics. John Bigler, Asset Manager at Danos spoke about how a fatality on the job had him review his company’s fleet policies, with a focus on monitoring violations, like speeding.

The new policies included both a carrot and stick approach, with good drivers benefiting from a rewards program (including cash awards) and peer recognition. KPIs were used to monitor the situation, with monthly reports sent to both the fleet manager, as well as company leadership.

The fact that executives were involved added weight to the issue. No longer was it just the fleet manager trying to improve driver performance. He now had the backing of top management.

The results were impressive. Two-and-a-half years after the new fleet policies were implemented, the number of accidents had gone down by 40%, and the severity of each accident had diminished as well. The number of violations fell by 300%, the company saved $1 million in insurance costs, and they’re also benefitting from lower insurance rates.

Industry mega trends

Another panel discussion, moderated by Craig Pierce, Senior VP of Sales at Holman looked at key trends in the industry. The panel agreed that vehicle prices are going up and that affordability is a key concern for fleets.

Ed Powell, Director of Consulting Services at Holman explained that vehicle prices are never going to go down. “Vehicles aren’t going to get cheaper,” he said, adding that fleet professionals need to communicate this fact with management. “They must also understand that the cost to repair vehicles, if they want to keep them longer, isn’t going to go down either,” he added.

Ted Davis, Senior VP of Upfitting at Holman suggested one way that fleets can keep costs down. “Understand the purpose of the vehicles in your fleet and ask yourself what you can do to make sure those vehicles aren’t overbuilt, but built for purpose,” he said.

Powell reminded fleet professional, “if you’re maintaining your vehicles well, you’re going to get more for those vehicles at resale, because prices in the used car market are higher as well.” This, in turn, should help keep costs down when purchasing new vehicles at higher prices.

The program concluded with a keynote presentation by B.C. native, Eric Termuende, author and co-founder of NoW of Work. He explained that although no one knows what the future holds, the key to success is not to focus on what the next month or next year will bring. Instead, organizations need to focus on building a team that will succeed, no matter what the future looks like.