Retreading: The Cost-Effective, Eco-Friendly Tire Solution

At RTS Canada’s Montréal plant, retreading is their specialty. Martin Collet and Trevor Schotsman have owned this company for three years. Founded in 1995, it was created to showcase Italian technology. Even today, most of the tires retreaded at RTS Canada are processed using that same technology, which features a new jointless tread bonded to the original casing.

RTS Canada is one of about fifteen companies of varying sizes in Quebec working in the commercial transport tire retreading industry. In this 30,000 sq. ft. facility, 40 employees recondition between 40,000 and 50,000 tires for Class 4 to 8 trucks each year. Production potential is as high as 65,000 tires, but the market is currently unsettled. Challenges include the massive influx of low-end Asian commercial tires sold at clearance prices, and the fact that many fleet managers are reluctant to consider retreaded tires.

“We conducted a 12-month study on commercial tires destined for recycling in Quebec, and found that 58% of the tires we examined could have been retreaded,” explains Collet. “That’s a shameful waste of resources. After fuel, tires are the main source of pollution in transport.” The plant was completely transformed under the new owners to improve processes, maintain the high quality of its products, and increase production capacity.

RTS Canada sources tires directly from dealers that service commercial fleets. They collect used tires, and deliver the retreaded ones ordered by their customers. For Collet and his Toronto-based partner Trevor Schotsman, prolonging the life of commercial tires is a commitment to protecting the environment and conserving natural resources.

Once at the plant, casings are thoroughly inspected to determine whether they can receive a new tread before returning to service. This detailed inspection is carried out by a shearography machine, which can detect internal defects invisible even to an expert eye.

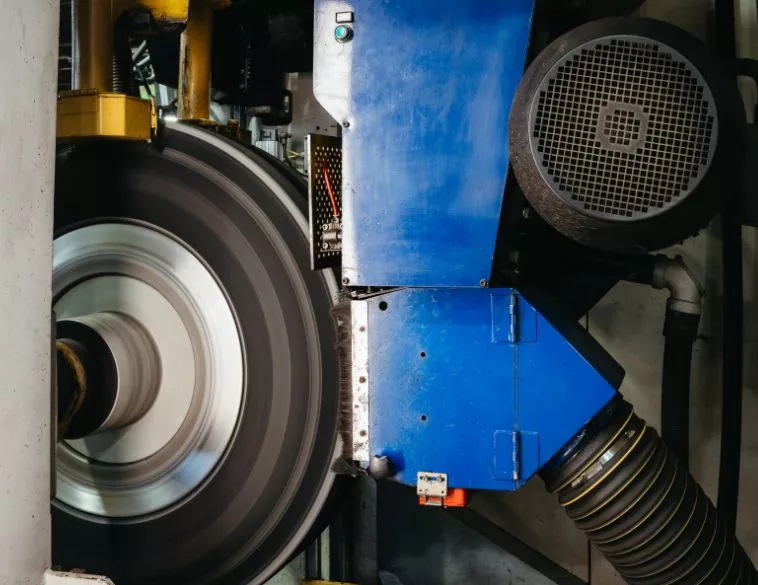

Tires that pass this test are buffed, meaning the remaining tread is removed (about 7 kg of recovered material is recycled), and prepared to receive a new one. If needed, brushing and manual casing repairs are carried out before the tire is fitted with the new tread. The assembly then undergoes vulcanization, which gives the raw rubber greater elasticity and increased resistance. A final inspection is followed by an additional shearography check to ensure every batch is perfectly cured before going to market.

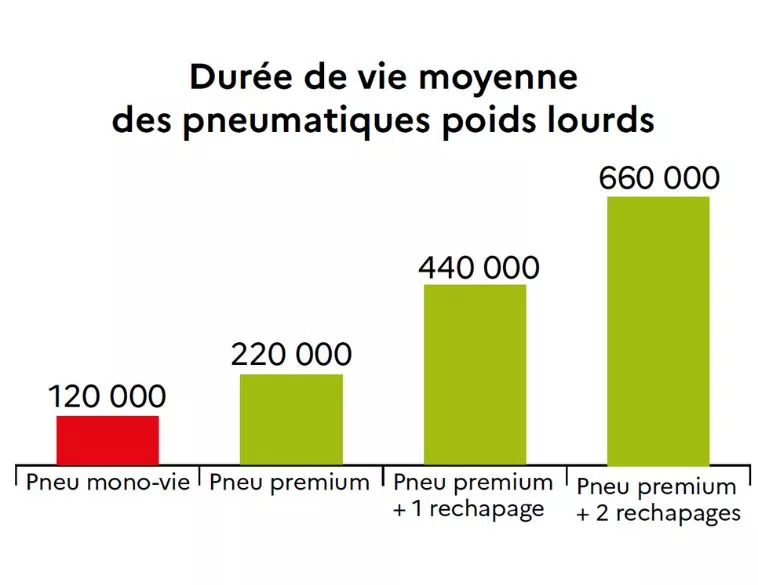

A high-quality tire can be retreaded three times, and in some recent cases, with certain brands and models, up to four times, depending on casing condition. This means the mileage of a casing can often be quadrupled before it needs to be recycled. For fleet managers, this is where retreading helps recover the initial investment in a premium tire. Low-end tires may be retreaded once or twice, but rarely a third time, especially with unknown brands that have become more common in the past five years.

A visit to RTS Canada’s impressive facility makes it clear that retreaded tires deserve better recognition. Their quality is closely monitored, and the product is virtually custom-made. “Tread compounds come in various versions, including extreme-performance designs that can be combined with SmartWay technology to reduce rolling resistance,” explains Collet. “Customers can choose the product that best suits them from a selection of 33 different treads (https://www.rts-canada.com/en/shop/), depending on the application, and whether it is for tractors or trailers.”

The company is confident in the quality of the tires they’ve given a second, third, and even fourth life to. So much so, that they offer a warranty program of up to five years, under certain conditions.

“For both economic and environmental reasons, we want fleet managers to seriously consider commercial retreaded tires as a viable option,” concludes Collet.

Watch a short video showing the main production steps for retreaded tires at this facility: https://youtu.be/Eq-hvhdbaqk